Battery Management System- for safe and reliable battery operations

The growing prevalence of electric vehicles and smart grids and the shift toward renewable energy sources have increased the value of batteries. Maximum performance, safe operation, and optimal lifespan under varied charge-discharge and environmental conditions have become essential for large-scale power distribution in factories, industries, and infrastructures. With the increase in oil prices and pollution levels worldwide, all businesses must take steps to reduce their carbon footprints, resulting; in many nations tightening up their rules on power plants and transmission systems. Reducing power’s adverse effects on the environment and the economy makes the research, development, and management of batteries crucial. Because of this, businesses have had to create and rely on an innovative and flexible solution, thus developing battery management systems (BMS).

This article explores how innovative technologies and solutions help industries to manage battery power. Let’s begin with knowing what is BMS and its functionalities.

Battery Management System

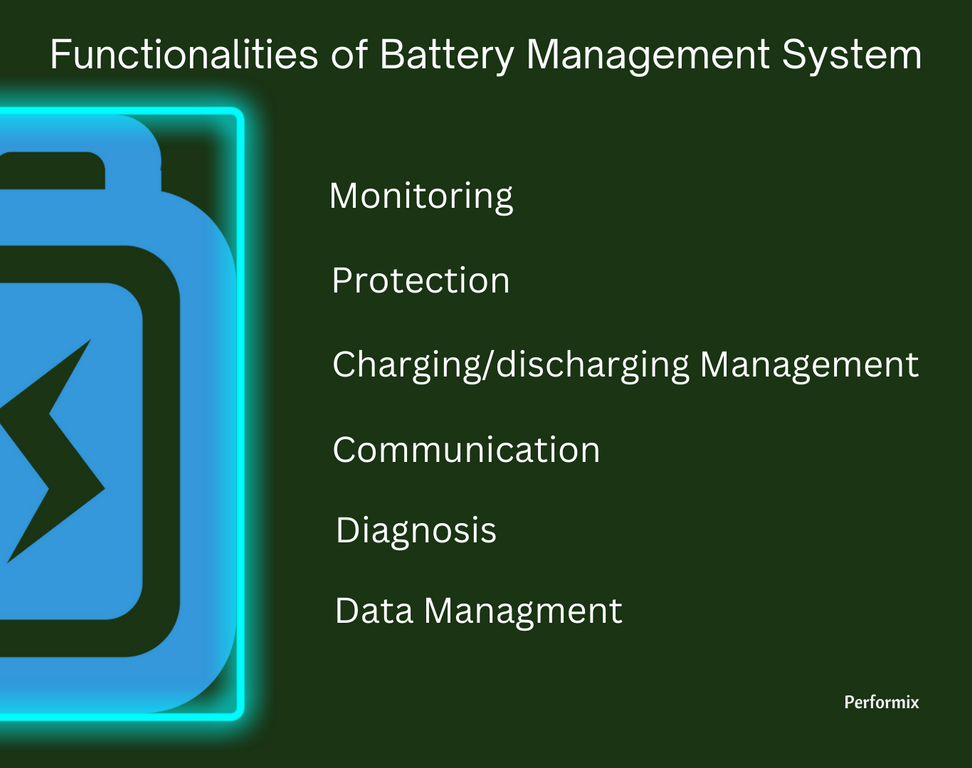

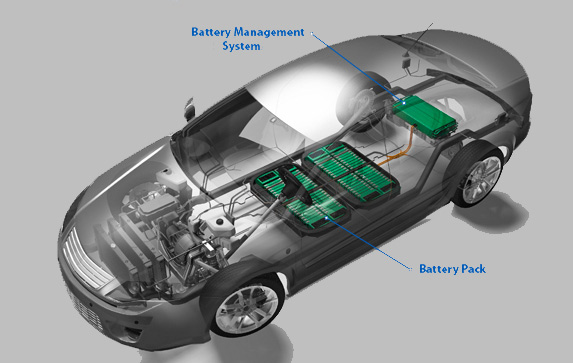

A battery management system (BMS) is a technology used to monitor a battery pack. A battery pack is an assembly of battery cells that are electrically organized in a row x-column matrix configuration. This configuration enables the delivery of a targeted range of voltage and current for a while against expected load scenarios. The security of the battery relies on the BMS, which continually checks things like voltage and temperature. In addition to shortening the battery’s lifespan, it can monitor overheating and overcharging that increase the risk of an accident, making BMS necessary. The BMS’s flexibility in adapting to specific needs is its greatest strength- which means it can be customizable. BMS helps with

- Keeping track of the battery

- Defending batteries from harm

- Trying to gauge the health of the battery

- Constantly improving battery performance

- Notifying external devices of operational status

It reports on the “state of charge” and “state of health.”

- SoC: Gives details about the battery, such as how much power is left.

- SoH: Gives Information on the battery’s age-related health.

Such reports can make the battery more secure and efficient.

To rephrase, BMS is a must-have for the battery’s and the user’s protection. The BMS regulates the charging current to save the battery from being overcharged or discharged below its minimum capacity. By monitoring the battery’s charge and discharge levels, BMS can help keep the battery in optimal condition.

Technologies for BMS – the dominance of Digital Twin

The battery management system incorporates a number of technologies, but now that the Digital Twin (DT) has been introduced, it is possible to integrate these technologies to provide real-time battery management.

The core concept of DT is to seamlessly merge the real and virtual worlds in real-time through the use of various cutting-edge technologies. To move from digital modeling to actualizing intelligent control, DT necessitates using big data, AI, IoT, cloud computing, blockchain, and other formidable platforms. Here, we’ll provide an overview of how these essential technologies can be used in DT.

Digital Twin and Big Data

The vast amounts of data stored in the DT can be used by big data to model and foresee events and processes in the physical world. Security, integration, storage, management, interactive analysis, visualization, and more are all necessities for big data platforms. Sensor data, model generation data, and simulated and actual fusion data are all combined in the twin data set in a BMS.

Digital Twin and AI

Artificial intelligence (AI) is the technological simulation of human intelligence. The four primary branches of artificial intelligence are machine learning, NLP, speech recognition, and automated visual perception. To draw conclusions or make forecasts, machine learning algorithms automatically examine data, extract rules from that data, and apply those rules. The DT can simulate, diagnose, predict, and optimize control thanks to its high-fidelity virtual model, massive twin data, and real-time, bidirectional dynamic interaction. As a result of matching the most effective intelligent algorithms with fully formed services having varying requirements, AI can analyze, integrate, and deeply mine twin data. Data value and the responsiveness and accuracy of different functions can be significantly increased with the help of AI in DT.

Digital Twin and Cloud

Cloud storage is necessary because traditional storage methods can’t keep up with the volume and variety of data generated today. Additional calculations are needed for complex physical systems because DT necessitates real-time model simulation optimization, behavior prediction, Etc. The complexity of algorithms and the volume of data used by modern control systems are growing making the embedded processors underutilized. The system could theoretically be updated in real time due to cloud computing’s processing power. Shortly, the cloud will be used for everything, including data processing, analysis, and control decisions. Researchers are currently focusing on cloud BMS because they see it as a promising field with excellent growth potential. For processing this massive data set and intricate algorithm, DT will utilize a cloud computing infrastructure.

Digital Twin and Internet of Things

The hardware and software of the Internet of Things act as “staircases” that transport data from the physical world into the digital realm. To transmit and process data, the IoT primarily uses the interfaces of various devices (RFID, sensors) to link physical objects to the Internet. In the case of an incomplete physical mechanism and input data, battery DT utilizes the twin data’s prominent data characteristics to predict the battery’s future state using machine learning technology.

Digital Twin and Blockchain

To put it simply, blockchain is a novel application scheme made possible by employing technologies like decentralized data storage and peer-to-peer transmission. The blockchain combines a decentralized ledger, a consensus mechanism, a smart contract, and cryptography. Data integration and analysis are at the heart of DT, but data management has potential dangers like data loss and malicious modification. Data credibility must be addressed if there is to be any hope of establishing faith in the system. The main benefits of combining DT with blockchain are visible in the realization of DT interaction and the assurance that data are unmodified during storage and transmission.

Cybersecurity

BMS security is becoming increasingly important as more battery systems incorporate internet connectivity for features like intelligent monitoring, control, and maintenance. So, once you’ve settled on the hardware and technical particulars, it’s time to think about how to keep your BMS secure.

Of course, modern technology is needed for battery upkeep, but how about tracking its status and retrieving data on its performance? Here’s where software comes in: different software solutions help convey the test parameter by integrating with the hardware and technologies of battery power.

Softwares for BMS

Battery management system (BMS) software provides a window into the battery, revealing its actual condition. Both the battery’s characteristics and its stability in operation are estimated. Complex BMS software development is necessary for multifunctional battery management systems. For instance, software in a control unit regulates the cooperation and interaction of BMS parts. To collect and transmit battery data, a measuring unit requires software. A BMS can take direct voltage, current, and temperature readings, among other physical parameters and also estimates the battery states related to physical quantities, chemical composition, and the battery’s operating environment. Below are the four parameters that BMS software can track.

- State-of-charge (SOC)

- State-of-health (SOH)

- State-of-energy (SOE)

- State-of-power (SOP)

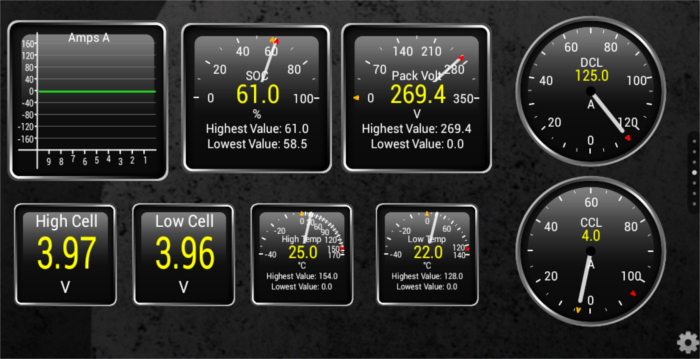

However, there is currently no standard method for quantifying these features, despite their potential importance in specific systems. Maintaining a reliable system is more important than a precise state estimate. This is where we can help. Building a more accurate mathematical model for battery state estimation is made possible through simulation in the development of BMS software. Our engineers develop models with the help of simulation programs like MATLAB and GNU Octave. Battery and operating environment behavior can be replicated with simulation. Various algorithms are used to implement battery models, which can be verified through simulation. Apart from the key parameters, these simulations also evaluate overvoltage, under voltage, overcurrent, and overheating. The Information is displayed on Human-Machine Interface (HMI) dashboard that is built using QT software. Information about the battery pack, the battery’s cells, and the battery’s lowest-level components are indicated through HMI, thus enabling the Battery Maintenance team to keep an eye on the battery’s status and parameters, turn on and off individual battery units, and deal with any issues that arise.

Do you know

Forecasts put the value of the global battery management systems market at $24.83 billion by 2027, expanding at a CAGR of 20.2%.

Use-Case

Electrical Vehicle (EV)

Battery electric vehicles have no combustion engine, fuel cell, or fuel tank. This category includes trucks, cars, buses, motorcycles, bicycles, and forklifts. Lithium-ion batteries power most electric cars today. Lithium-ion batteries have a high energy density (100-265wh/kg). They could catch fire under certain conditions. Hence, EVs must meet safety standards to protect drivers and vehicles. A battery management system (BMS) ensures an electric vehicle’s reliability, efficiency, and safety. It is responsible for maintaining the voltage consistent across the battery by keeping tabs on the battery’s State of Health (SOH), collecting relevant data, and regulating environmental factors that impact the cell.

EV BMS offers two significant functions.

- Overvoltage protection for battery safety.

- Accurate cell balancing optimizes energy storage performance.

BMS for Large-Scale Energy Storage

Power plants are the most common locations for large-scale energy systems, and these facilities require storage systems of varying sizes in case of outages or to provide backup power. Therefore, a BMS is a must-part of every power grid these days.

Advantages of BMS in large-scale units

- The analysis of BMS risk entails identifying the mode of connected loads in both standard and abnormal operations and analyzing hazard scenarios.

- Technical batteries are tested so that accidents like fires and explosions can be avoided and people aren’t hurt.

- Protecting users from potential fire and electric shock risks is a top priority in any BMS set.

- Sensors built into the BMS can report the battery’s voltage and temperature.

- BMS sensors report the amount of current flowing through the battery packs and transmit that data to the BMS control module.

BMS is mandatory for various fields, including transportation, healthcare (hospitals), fleet, power grid, telecommunications, aerospace, defense, electronics, and electric vehicles. Besides considering its usefulness, BMS must be installed in large power plants in strict accordance with applicable standards and regulations. All technology stack layers must remain unchanged in energy storage and distribution management guidelines. Recent studies show that North America dominates the BMS market. This is due to the region’s abundance of significant automotive manufacturers and advanced grid management and telecom systems, which are highly beneficial to spreading BMS throughout the region.

Solutions offered by Performix

Our storage application-agnostic battery management solutions can be tailored to work with various battery types, module sizes, and stack configurations. We provide a BMS that can be set up virtually anywhere.

- Utility grid help

- Facilities for business and industry

- Energy storage for homes

- Automotive used for specialized vehicles

- Solar / Wind Energy Storage Systems

- Racing Vehicles

Delivered Possibilities and features:

1. Overload/overvoltage protection

Maintenance of battery cycle life by preventing damage from overcharging and discharging.

2. Controlling Temperature

Overheating and underheat protection with fully automated cooling/heating fan controls.

3. Condition Tracking

Measuring battery capacity and tracking the internal resistance of each cell.

4. Timely updates

The PCS can access battery performance thresholds and real-time voltage, current, temperature, State of Charge (SOC), and Depth of Discharge (DOD) data.

5. Allows ESS’s environmental controls and other safety systems direct access to battery data in real-time.

6. Compatible with Li-Ion batteries

Our solutions work with a wide range of cell voltages. They work with almost all lithium-ion batteries and some NiMH batteries as well.

7. Systems for identifying noise and malfunctions

Robust construction to block electrical noise and a detector for when active isolation fails between the battery and the chassis.

8. Quick and easy access to data – Creates an Excel-compatible file of the exported data.

9. Allows “Service Mode” to be activated for maintenance and troubleshooting

10. Solutions that are compatible with Windows XP, Windows 7, and Windows 10.

Peformix is a versatile platform that facilitates the integration of the BMS’s hardware and software components using cutting-edge technologies to save money and safeguard your business’s energy consumption. We provide a complete BMS solution, including solutions for battery management, ESS control via multiple stacks, and safety threshold applications. We offer an easy-to-use Operator Interface that lets you set up your BMS for various battery chemistries and tailor its operational parameters to your specific use case. You can view, log, and analyze data with our built-in programs, allowing for comprehensive predictive power control.

Start Investing in BMS

By anticipating thermal capacities in electricity grids, batteries, and renewable energy plants, energy storage management systems boost the value of energy storage. With Digital Twin technology, a BMS with customized software eases transmission and distribution network congestion and keeps the Volt-Ampere Reactive (VAR) under control in real-time. Many industries have already been pioneers of BMS with cutting-edge technologies. Nikola Power, a startup based in the United States, develops intelligent energy storage software to optimize battery management for renewable power generation and distribution networks. The startup’s batteries are managed in real-time using proprietary algorithms. Behind-the-meter storage system cost savings are also maximized.

The good news is that corporates and industries are mindful of global environmental goals and thus want to build systems that check CO2 emissions and evaluate hazardous chemicals and gas. As a result, companies such as ours, which specialize in creating software, have added the goal of integrating a sizable portion of renewable energy systems (RES) by developing and deploying customized flexibility services. Also, with the rise of electrical vehicles (e-bikes, e-cars) which is seen as the future of transportation switching from petrol & diesel vehicles, the BMS is expanding its scope focusing to save energy with accelerated performance.

We have the technical answers to meet the exponential expansion of renewable energy sources; are you prepared to invest in them?

Check out the cost of software development at Performix and contact us by phone or email to receive the most accurate estimate for your project.